Project Example:- Ester Reduction

Reactions typically complete after 2 h with above conditions in batch.

Alcohols tend to precipitate out of solution as reaction progresses.

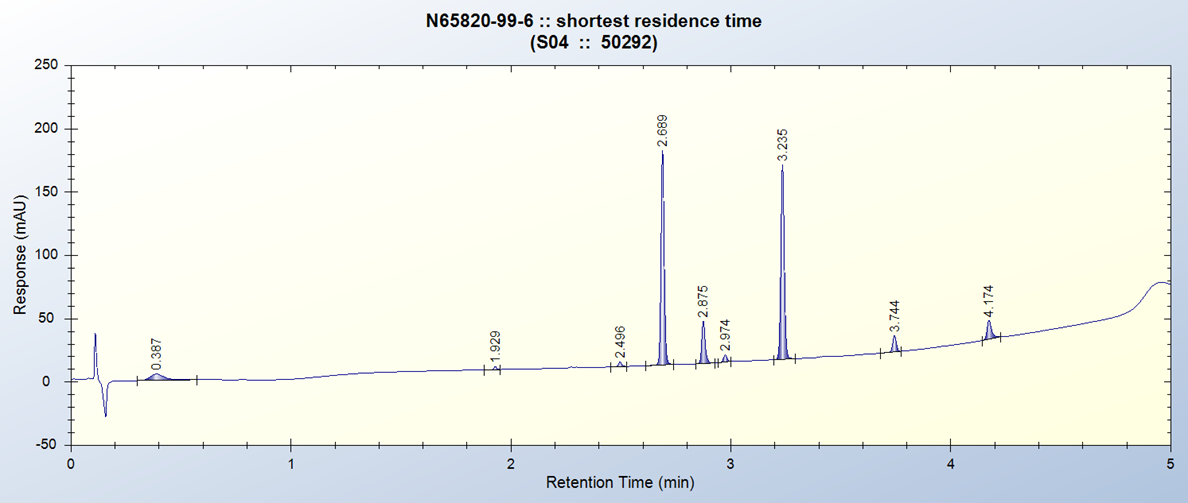

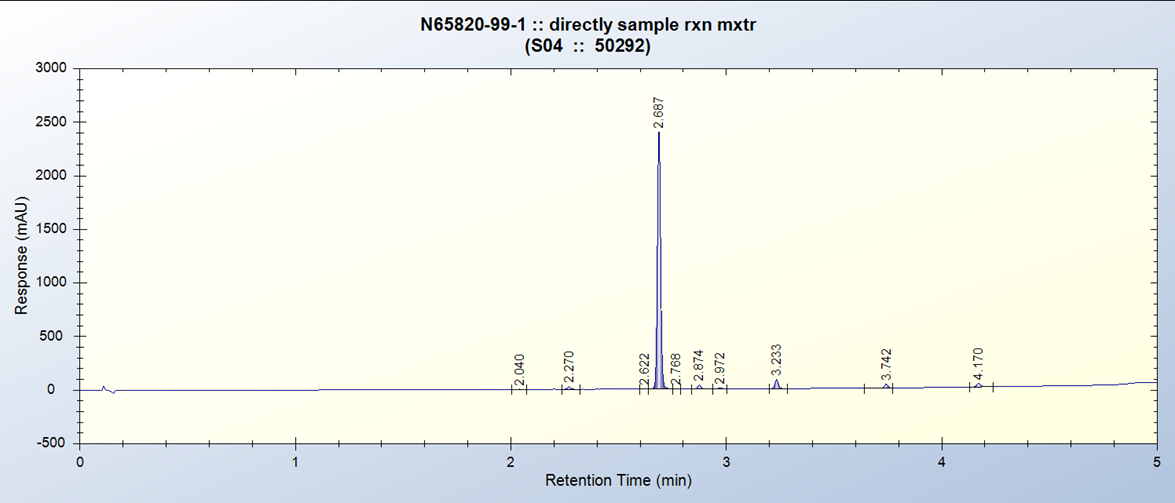

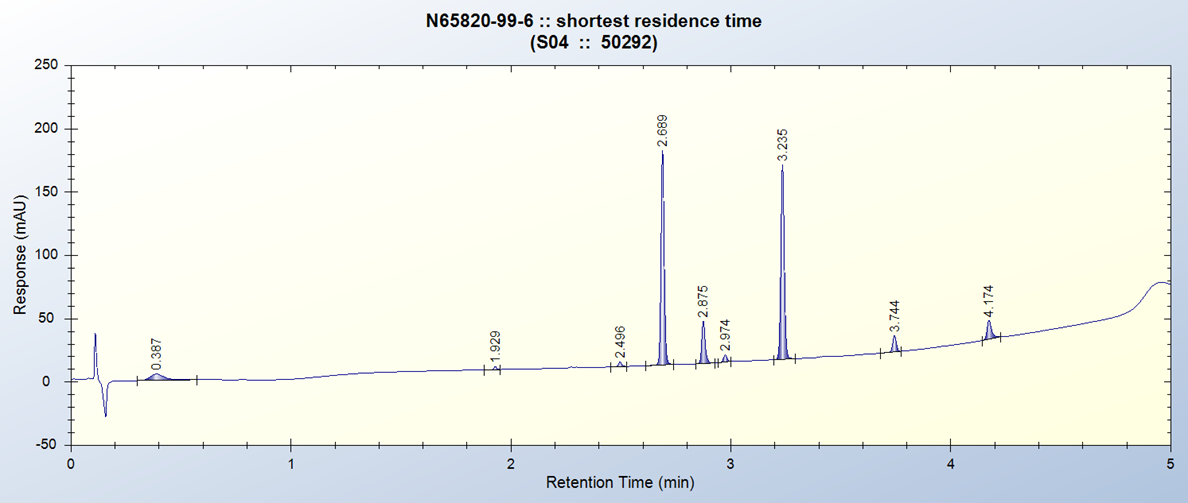

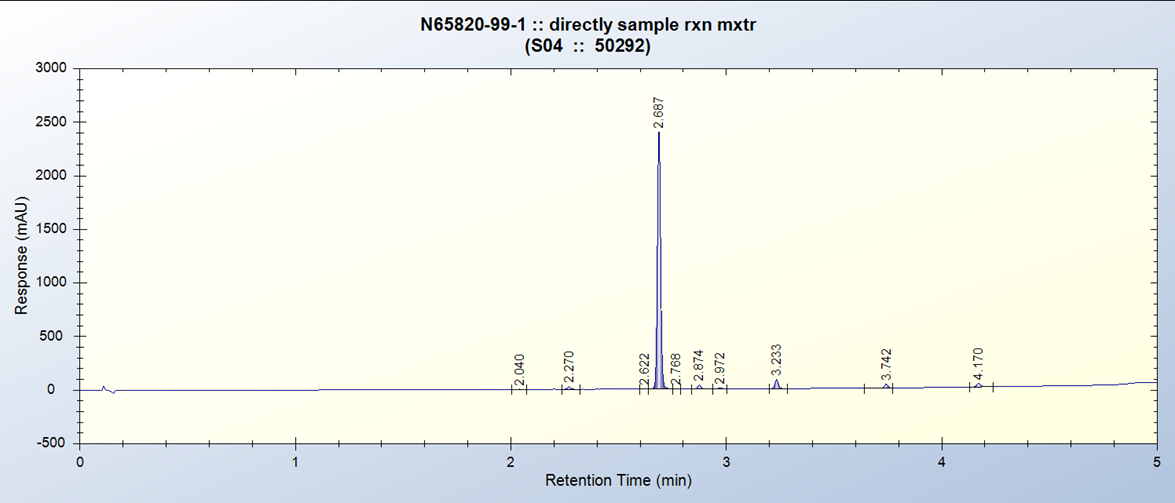

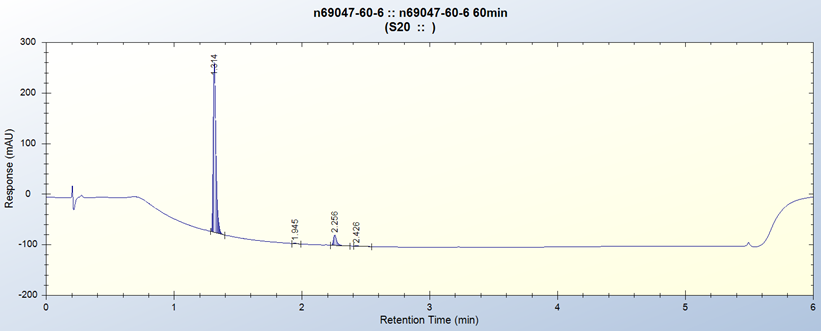

54 minute residence time DART-DM7 Flow Reactor.

DART-DM reactors can be configured to meet the needs of many different synthetic and biological processes.

DART-DM reactors can process reactions involving gases, liquids and suspended solids, (slurries). Photochemistry versions of DART-DM are now also available opening up new areas of processing and manufacturing where catalysts are used in photochemistry.

With the kind permission of our customers; below are just a few examples of the types of reactions that can be undertaken in DART.

5 independent HTF zones

Hastelloy or Stainless Steel

Choice of drives, automation and instrumentation

5 Independent HTF zones

Hastelloy or Stainless Steel

Chioce of wavelengths.

Single tube design

Hastelloy or Stainless Steel

2 Working volumes of 60 and 155ml

2 Heat transfer zones

Handles highly viscous materials and high solids concentrations.

Single tube design

Hastelloy or Stainless Steel

Taylor Vortex Mixing

Gas membrane for safe handling of O2

2 Electric Heat transfer zones

Hastelloy or Stainless Steel

2 independent Heat transfer zones

Choice of Drives, automation and instrumentation

Photochem module option

2 Heat Transfer Zones

Hastelloy or Stainless Steel

14ml Working volume

Handles viscous material and high solids concentrations

Electrically heated

PEEK and Borosilicate Glass

Taylor Vortex Mixing

7ml Working volume

2 Heat Transfer Zones

Hastelloy or Stainless Steel

14ml Working Volume

Chioce of drives automation and instrumentation

Photochem module option

25ml Working Volume

PTFE/PFA/Borosilicate Glass construction

Photochemistry with suspended solids.

500ml nominal working volume

Hastelloy or Stainless Steel

Project Example:- Ester Reduction

Project Example:- NO2 Reduction

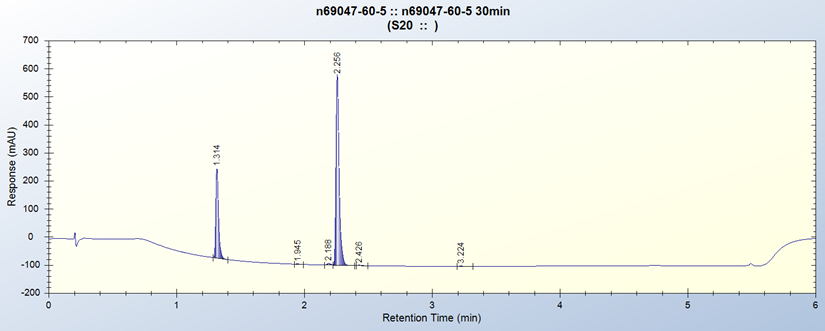

30min Residence Time in DART-DM7x7 Flow Reactor

It is widely known that that a high CO2 mass transfer rate is vital to the

design of better bioreactors for CO2

mitigation. By comparison with traditional sparging methodologies, the use of a DART reactor greatly increases the residence time of the gas in the algae culture.

Ruthenium-Catalyzed Ester Reductions Applied to Pharmaceutical Intermediates

https://www.nature.com/articles/s41467-019-13988-4

Carbon Capture

https://www1.chester.ac.uk/autichem-ltd

Teaching and learning

https://link.springer.com/article/10.1007/s41981-020-00118-1